Back to menu

View all Our Products

Door Hardware

Joinery Hardware

Handles and Knobs

Hinges

Sliding Hardware

Lighting

Ironmongery Ranges

Back to categories

View all Door Hardware

Dörepack - Ironmongery Kits

Door Straighteners

Door Closers

Door Furniture

Locks and Latches

Panic Hardware

Signage

Front Door Furniture

Seals

Accessories

Glass Door Fittings

Pocket Door Hardware

Back to Door Hardware

View all Door Closers

Concealed Overhead Door Closers

Concealed Side Mounted Closers

Electro Magnetic Door Closers

Floor Springs

Pivot Sets

Slide Arm Overhead Closers

Surface Mounted Overhead Closers

Back to Door Hardware

View all Locks and Latches

Budget Locks

Cylinder Locks

Digital Locks

Electronic Access Control

Forends, Strikes and Intumescent

Mortice Locks

Mortice Deadlocks

Mortice Escape Locks

Mortice Latches

Mortice Nightlatches

Mortice Sashlocks

Padlocks

Rebate Sets

Restricted Keys

Rim Locks

Safes

Tubular Deadbolts

Tubular Latches

Rim Nightlatches

Push Button

Cabinet Locks and Latches

Push to Close

Roller Catches

Gate Latches

Mortice/Rim Knobs

Door Latches

Flush Bolts

Security Bolts

Cottage Latches

Latch Sets

Deadlock Cases

Bathroom Locks

Back to Door Hardware

View all Signage

Bespoke Signs

Fire Door Signs

Numerals

Symbols

Letters

General Signage

Back to Door Hardware

View all Front Door Furniture

Door Viewers

Letter Plates

Knockers

Door Chains

Bell Pushes

Back to Door Hardware

View all Accessories

Door Bolts

Door Holders

Door Stops

Emergency Door Stops

Finger Protectors

Foot Pulls

Hat and Coat Hooks

Spindles and Fixings

Sills and Thresholds

Back to categories

View all Joinery Hardware

Drawer Runners and Box Systems

Cabinet Components

Kitchen Components

Panel Fixings

Lift Systems, Stays and Dampers

Door Straighteners

Assembly Devices and Jigs

Window Hardware

Workshop Consumables

Rails, Fixtures and Fittings

Back to Joinery Hardware

View all Drawer Runners and Box Systems

Accuride Runners

Ambialine

Ball Bearing Runners

Cutlery Trays and Dividers

Dovetail Drawers

Legrabox Drawers

Metabox Drawers

Movento Runners

Servo-Drive

Standard Runners

Tandembox Drawers

Tandem Runners

Heavy Duty Runners for Pull Out Storage

Back to Joinery Hardware

View all Cabinet Components

Cabinet Hanger Systems

Cable Outlets

Castors Feet and Legs

Fixing Materials

Glass Door Locks and Hinges

Magnetic Catches and Bolts

Plinth Feet

Push to Open

Cabinet Pulls

Cabinet Locks and Latches

Door Buffers and Dampers

Mirrors and Glass

Back to Joinery Hardware

View all Kitchen Components

Accessories

Legs

Taps

Towel Rails

Waste Bins

Wirework Storage

Worktop Bolts

Electrical Sockets and Plates

Power Docks

Hooks

Shelving

Ducting

Vents and Grilles

Back to Joinery Hardware

View all Panel Fixings

Button-fix

Connecting Fittings

Fastmount Installation Tools

Fastmount Low Profile LP Range

Fastmount Metal MC Range

Fastmount Panelsafe PS Range

Fastmount Standard PC Range

Fastmount Textile TC Range

Fastmount Very Low Profile VL Range

Back to Joinery Hardware

View all Lift Systems, Stays and Dampers

Aventos Lifts Systems

Stays and Dampers

Gas Struts

Back to Joinery Hardware

View all Window Hardware

Casement Fasteners

Casement Stays

Sash Lifts

Sash Fasteners

Fanlight Catches

Pole Hooks

Quadrant Stays

Espagnolettes

Sash Pulleys

Winders

Back to Joinery Hardware

View all Rails, Fixtures and Fittings

Bathroom Fittings

Office Fittings

Handrail Fittings

Wardrobe Fittings

Bedroom Fittings

Curtain Rail Fittings

Screws

Nails

Bolts

Mounting Brackets

Shelf Supports

Bookcase Strips and Studs

Back to categories

View all Handles and Knobs

Lever Handles

Door Knobs

Pull Handles

Cabinet Handles

Edge Pull Handles

Flush Pull Handles

Centre Door Knobs

Multi-Point Handles

Knurled Handles

Escutcheons

Turn and Release

Back to categories

View all Hinges

Heavy Duty Hinges

Blum Hinges

Salice Hinges

Butt, Parliament and Rise/Fall Hinges

Concealed Hinges

Continuous Hinges

Flush Hinges

Sprung Hinges

Gate, Tee and Strap Hinges

Torque Hinges

Pivot Hinges

Counter Flap Hinges

Back to Hinges

View all Blum Hinges

Accessories

Cover Caps

Mounting Plates

Face Frame Hinges

Hinges - Soft Close

Hinges - Non Soft Close

Back to Hinges

View all Salice Hinges

Salice Air - Concealed Hinges

Conecta Hidden Soft Close Hinges

Pacta Compact Hinges

Air Push to Open Hinges

Back to Hinges

View all Butt, Parliament and Rise/Fall Hinges

Butt Hinges

Parliament Hinges

Rise and Fall Butt Hinges

Tritech Hinges

Back to Hinges

View all Concealed Hinges

Tectus Hinges

Anselmi Hinges

3D Concealed Hinges

Soss Hinges

Concealed Cabinet Hinges

Hettich Hinges

Concealed Hinges for Overlay Doors

Back to categories

View all Sliding Hardware

Hawa Sliding Door Hardware

Coburn

Salice

Straight Sliding

Folding

Accuride Pocket Door

Slido

Multi-directional

Round the Corner

Blum Pocket System

Sugatsune Sliding Door Systems

Back to Sliding Hardware

View all Hawa Sliding Door Hardware

Hawa Acoustics

Hawa Clipo

Hawa Combino

Hawa Concepta

Hawa Junior

Hawa Media

Hawa Multifold

Hawa Porta - Straight Sliding

Hawa Super

Hawa Varioflex

Hawa Aperto

Back to Sliding Hardware

View all Salice

Exedra Pocket Door System

Exedra2 Smart Pocket Door System

Salice Accessories

Back to categories

View all Lighting

Bespoke Lighting Solutions

Cabinet, Plinth and Display Lighting

LED Tape and Profiles

Drivers and Power Supplies

Switches and Sensors

Ceiling Lights

Accessories

Clearance

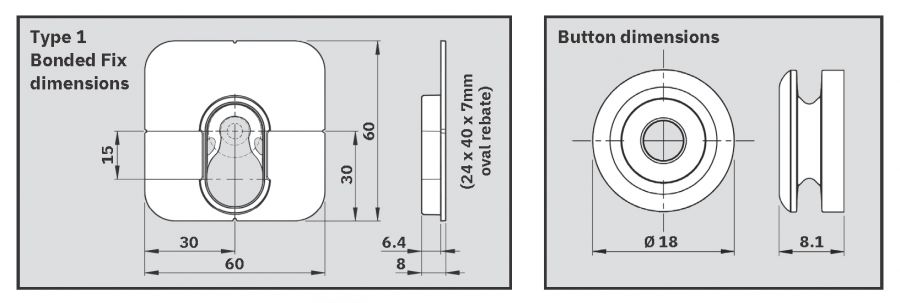

Button-fix™ - Type 1 - Bonded Fix + Button for CSK Wood Screw

utton-fix™ Type 1 - Bonded Fix + Button for CSK Wood Screw: The Ultimate Invisible Panel Fixing Unlock the power... More info

| Product name | Variant code | Data sheet | Price | Quantity | ||

|---|---|---|---|---|---|---|

| Button-fix™ - Type 1 - Bonded Fix + Button for CSK Wood Screw - Pack of 100 | In Stock | 171-017-11 | Download | £62.50 ex VAT |

|

Compare Button-fix™ - Type 1 - Bonded Fix + Button for CSK Wood Screw

utton-fix™ Type 1 - Bonded Fix + Button for CSK Wood Screw: The Ultimate Invisible Panel Fixing

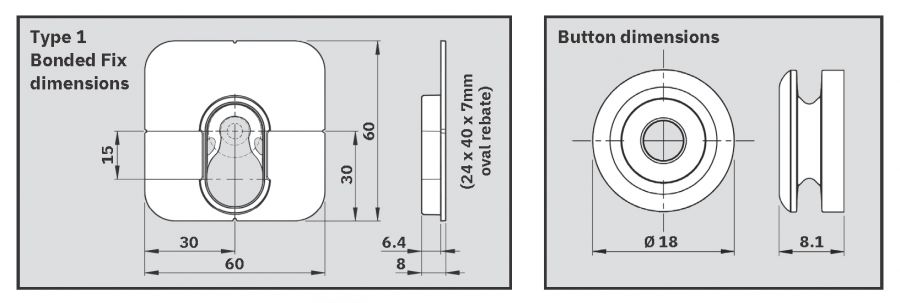

Unlock the power of secure, secret panel fixing with the revolutionary Button-fix™ Type 1 Bonded Fix + Button system. Engineered for professional installers, designers, and manufacturers, this ingenious fastener provides unmatched strength and the flexibility of a fully concealed, demountable connection. Say goodbye to unsightly screws and visible hardware—achieve a seamless, flush finish every time.

Key Features:

- Invisible Panel Fixing: Achieve a perfectly concealed mount for a clean, modern aesthetic.

- Bonding Flexibility: The Type 1 Bonded Fix is specifically designed for applications where screw fixing is impossible or impractical, allowing you to bond directly to thin, rigid, or specialist materials.

- High-Performance Strength: The robust, durable polymer construction (ABS Fix / 30% glass-filled Nylon Button) provides exceptional load-bearing capacity for panels, shelving, and cladding.

- Simple 'Slide & Click' Engagement: Panels effortlessly slide into place with an audible 'click,' confirming a secure lock. Panels can be removed in seconds for easy access to services or maintenance.

- Versatile Installation: Suitable for both surface-mounted and semi-rebated configurations. Allows for either drop-down or sideways panel assembly.

- Compatible Button: The included Button is designed for a 5mm Countersunk (CSK) Wood Screw, offering a reliable, strong attachment to the structural frame or panel substrate.

Typical Applications

The Button-fix™ Type 1 Bonded Fix is the go-to solution for a wide range of interior and display applications:

- Retail & Exhibition Displays: Quick assembly/disassembly of temporary structures, signage, and Point of Sale (POS) units.

- Commercial Interiors: Wall panelling, feature walls, and modular acoustic panels.

- Specialist Materials: Fixing panels made of Solid Surface (e.g., Corian®, Hanex®), compact laminate, glass, or metal sheeting that cannot be screwed.

- Upholstery & Furniture: Securing removable upholstered panels, banquette seating, and cladding reception desks.

Type 1 Bonded is widely used for:

- Exhibition and point of sale displays

- Signage

- Transport interior panels

- Wall panelling with thin or lightweight materials

- Laminate sheets of up to 12 mm thick

Technical Specifications

| Feature | Fix (Bonded Component) | Button (Screw Component) |

| Material | ABS Polymer | Nylon PA6, 30% Glass Filled |

| Connection Type | Face-to-Face Parallel Panels | Face-to-Face Parallel Panels |

| Engagement | Slide & Click (Drop-down or Sideways) | Slide & Click |

| Fixing Method | Structural Adhesive Bonding | 5mm Diametre CSK Wood Screw |

| Panel Thickness | No minimum restriction (ideal for thin materials) | > 15mm recommended for full screw purchase |

| Reversibility | Surface-mounted or Semi-rebated | - |

| Guide Load | Up to 80kg per 4 Fixes (when bonded correctly) | - |

| Country of Origin | Made in the UK | Made in the UK |

Frequently Asked Questions (FAQ)

Q: What adhesive should I use with the Type 1 Bonded Fix?

A: Use a structural adhesive suitable for bonding ABS plastic to your panel material. Two-part structural acrylic adhesives (like Penloc or 3M Scotch-Weld equivalents) are highly recommended for a strong, reliable bond. Always consult the adhesive manufacturer's specifications.

Q: Can I use this fixing system outdoors?

A: Button-fix is warranted for internal use only. While the polymer is durable, the bonded connection is not covered by the warranty for external use or areas exposed to direct, prolonged sunlight.

Q: How do I ensure perfect alignment when installing the panels?

A: We strongly recommend using the optional Button-fix Marker Tool accessory. It snaps into the Fixes and leaves precise indents on the second panel, perfectly marking the position for the Buttons, virtually eliminating measuring errors.

Q: What is the minimum panel gap when installed?

A: The gap between the two panels is determined by the installation configuration. When the fix is surface-mounted, a typical 8mm gap is maintained. When semi-rebated, the gap is reduced.

Button-fix vs. Traditional Cleats/Fasteners

| Feature | Button-fix™ Type 1 Bonded | Traditional Split Batten / French Cleat | Hook and Loop Fastener (Velcro) |

| Engagement | Slide & Click Lock (Secure) | Drop-in (Gravity reliant) | Pressure Adhesion (Less Secure) |

| Strength/Load | Excellent - Verified for load-bearing applications. | Good - Primarily for vertical loads. | Fair - Limited to lightweight panels. |

| Removability | Quick & Easy - Secured by design, demountable in seconds. | Requires upward clearance, can be difficult. | Can degrade over time, less precise. |

| Bonding Option | Yes - Ideal for thin/non-screwable materials. | No - Always requires mechanical fixing. | Yes - But adhesion is the primary load-bearer. |

| Aesthetics | Completely Concealed | Often visible from the side/top. | Can require deep rebating to be fully hidden. |

Delivery Service

Built for the trade. Delivered when you need it.

We dispatch daily using our own fleet across the South West and surrounding regions, with regular weekday routes making next-day supply a realistic option in many areas.

Beyond our direct routes, we use carefully selected delivery partners to ensure the same reliable service and safe handling nationwide.

Customer Collection

Need it today?

Order online or through our sales team and collect direct from us.

- Ready in as little as 3 hours

- Order before 3pm for same-day collection

7 Cavalier Road, Heathfield Industrial Estate, Newton Abbot, TQ12 6TQ

Connect

© Copyright 2026 SWS Hardware. All rights reserved.

This website uses cookies to ensure you get the best experience. Learn more